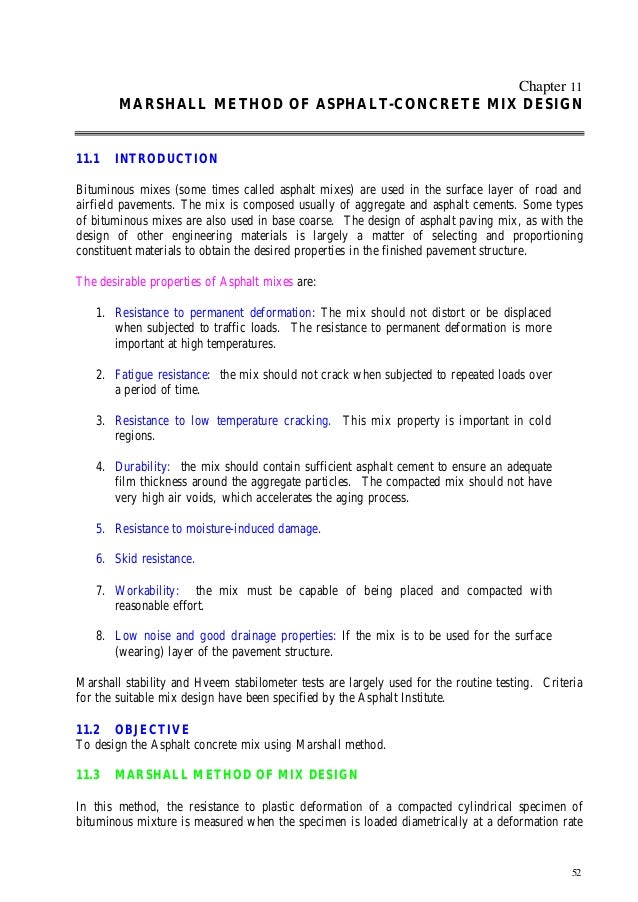

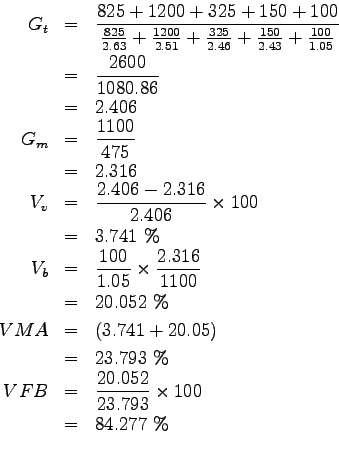

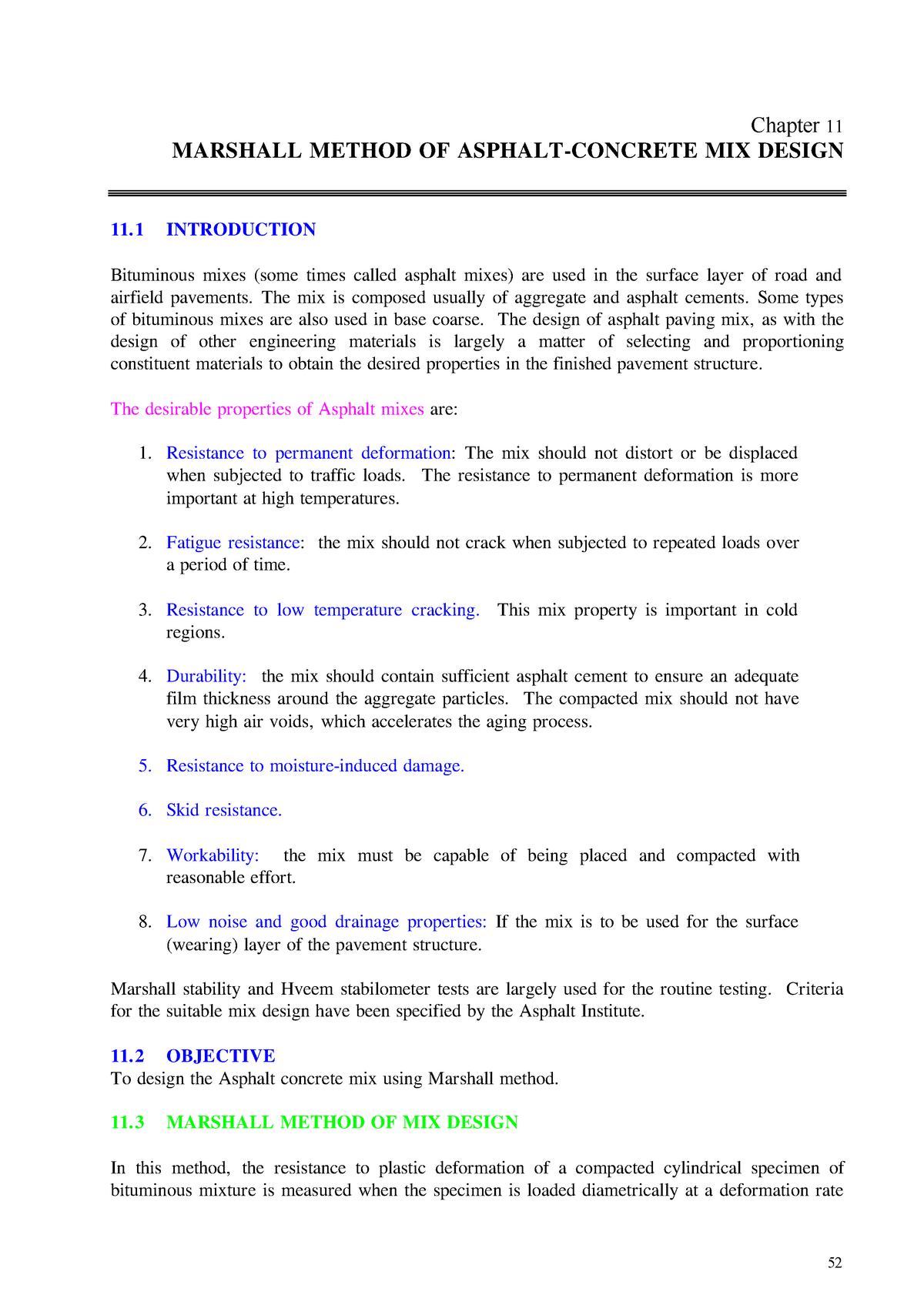

If mix composition is determined as percent by weight of the total mixture. The following materials.

The two principle features of the Marshall method of mix design are a density-voids analysis.

. The same mixcompaction temperatures were used for both the Marshall and SUPERP A VETM Level I mix design procedures. Students are also required to complete standard forms for the measurements and calculations obtained through the design process. Of 50 mm per minute.

Asphalt lab report Abstract This monthly report will highlight the many benefits of asphalt testing in terms of Engineering. WVU laboratory and shipped to the laboratories for compaction and testing using the Marshall method. The stability portion of the test measures the maximum load supported by the test specimen at a loading rate of 508 mmminute.

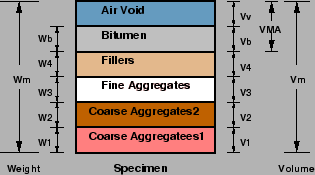

These are prepared using a specified procedure for heating mixing and compacting the asphalt-aggregate mixture. VMA voids in mineral aggregate percent of bulk vol Gsb bulk specific gravity of aggregate. 6 Figure 1 sb Where.

22nd MARCH 2018 TITTLE. There are two major features of the Marshall method of mix design. Marshal mix design test done in IIT BHUBANESWAR transport labflexible pavement design.

The weight of hammer is 454 kg and height of fall is 457 cm. The Marshall stability of the mix is defined as the maximum load carried by the specimen at a standard test temperature of 60C. The compacted specimen should have a thickness of 635 30mm.

F5 MARSHALL MIX DESIGN MEMBERS. To complete the Marshall Mix design students are required to write a detailed report using the results of the work done with a discussion of the results and conclusions drawn. Determine the density of each pill and calculate the average density γ Determine the specific gravity for each of the compacted pills and.

HK01 CIVIL ENGINEERING PROGRAM FACULTY OF CIVL ENGINEERING UNIVERSITY MALAYSIA SABAH KA31802 LABORATORY OF GEOTHECHNIC HIGHWAY DUE DATE. Key Words Marshall Variability Asphalt mix design 18. The aggregate and asphalt were mix together at.

A local asphalt mix producers 19 mm E-1 mix design was used to incorporate the glass aggregates into and to provide a standard asphalt mix to which mix properties could be compared. The Marshall sample is weighted to get the dry air mass and surface dry mass. Load is applied to the specimen till failure and the maximum load is designated as stability.

Lab mixing and compaction temperatures for all mixtures were selected in accordance with viscosity criteria stated by the Asphalt Institute in MS-2 U. From the results of these tests within-laboratory and between laboratory precision statements were developed for 102mm and 152mm Marshall test specimens. The compacting temperature may be about 135C for 6070 grade bitumen.

Before breaking the pills. 0duvkdoo 0l hvljq 6whsv 6hohfw dq dvskdow fhphqw vxlwdeoh iru wkh folpdwh 6hohfw djjuhjdwhv wkdw phhw wkh vxlwdelolw fulwhuld uhdwh dq djjuhjdwh eohqg wkdw phhwv wkh judgdwlrq fulwhuld. HK01 CIVIL ENGINEERING PROGRAM FACULTY OF CIVL ENGINEERING UNIVERSITY MALAYSIA SABAH KA31802 OF.

IRC 37The Marshall stability and flow test provides the performance. Temperature 140⁰C - 160⁰C. Considered for any mix design method.

The mix is placed in the mould and compacted by a rammer with about 75 blows on each side. The mix components as listed on this design were used to perform our work. Gmb bulk specific gravity of compacted mixture.

Download View Marshall Mix Design Lab Report as PDF for free. The basket was placed with the Marshall sample not. Asphalt binder vs measured values.

The Marshall stability and flow test provides the performance prediction measure for the Marshall mix design method. 2nd semester 1433H CE432-Highway Engineering LABORATORY MARSHALL MIX DESIGN PROJECT f Project Details Group 1 Group 2 Group 3 Group 4 Group 5 Mix 1 Mix 2 Mix 3 Mix 4 Mix 5 Binder 4 45 5 55 60 Content 1 Prepare three pills and compact 75 blows each side. View Lab Report - Marshall test from CIVIL ENGI CE444 at Jordan University of Science Tech.

I density-voids analysis and ii stability-flow tests. The Marshall method uses standard test specimens of 635 mm height by a 1016 mm diameter. Mix 1 Group 2 Mix 2 Group 3 Mix 3 Group 4 Mix 4 Group 5 Mix 5 Binder Content 4 45 5 55 60 1 Prepare three pills and compact 75 blows each side.

View Lab Report - 379142956-Marshall-Mix-Design-Lab-Reportdocx from MTR 241 at Seneca College. This site is like the Google for academics science and research. Number of blows was used in this test is 75 blows for both face top and bottom.

The Marshall method as presented here is applicable only to. The SHRP conducted a 50 million research effort to develop a Superpave mix design as a new concept for the design of bituminous mixes. The main objective is to train candidates in the correct performance of the standard laboratory asphalt tests f ASPHALT LAB REPORT August 31 2017 Contents 1.

The main objective of the present research is the. KT-15 Ps aggregate percent by total dry weight of mixture. Share Marshall Mix Design Lab Report.

Determine the density of each pill and calculate the. VMA 100 - G P G mb s Eq. A copyof the mix design report is included in Appendix B.

18 Full PDFs related to this paper.

Calculations For The Marshall Mix Design Of Bituminous Mixtures Pdf Free Download

1 Sieve Analysis Of Aggregate For Marshall Mix Design Download Gn Racesociety Com

Marshall Stability Test For Bitumen Mixture We Civil Engineers

Marshall Mix Design Question Pdf Marshall Mix Design Tutorial 1 A Mix Made With A Bitumen Content 6 By Mass S G 1 030 G Ml And An Aggregate Of Course Hero

Pdf Comparative Evaluation For Mix Design Of Marshall And Superpave Methods

11 Marshaltest Chapter 11 Marshall Method Of Asphalt Concrete Mix Design 11 1 Introduction Studocu

Doc Marshall Test Rania Sabbah Academia Edu

11 Marshaltest Chapter 11 Marshall Method Of Asphalt Concrete Mix Design 11 1 Introduction Studocu

Marshall Test Pdf Asphalt Road Surface

Calculations For The Marshall Mix Design Of Bituminous Mixtures Pdf Free Download

Marshall Test Lab Report Pdfcoffee Com

Design Mix Method Of Bitumenous Materials By Marshall Stability Method

Marshall Test Pdf Asphalt Road Surface

What Is Marshall Mix Design For Bituminous Materials Civil Engineering Portal Biggest Civil Engineering Information Sharing Website

Marshall Mix Design Lab Report Pdfcoffee Com

1 Sieve Analysis Of Aggregate For Marshall Mix Design Download Gn Racesociety Com